Description

Kraft paper bags are an eco-friendly, durable, and cost-effective packaging solution widely used for retail, gifting, food, and industrial packaging. Our range includes kraft bag paper, paper bag kraft paper, brown kraft paper bag, white kraft paper bag, and printed kraft paper bags, designed to meet both small and bulk packaging requirements.

We are trusted kraft paper bag manufacturers in India, offering kraft paper carry bags, kraft paper shopping bags, kraft paper gift bags, kraft paper bag with handle, and kraft paper carrier bags in multiple sizes and GSM options. These bags are ideal for retail stores, boutiques, sweet shops, grocery packaging, apparel brands, and corporate gifting.

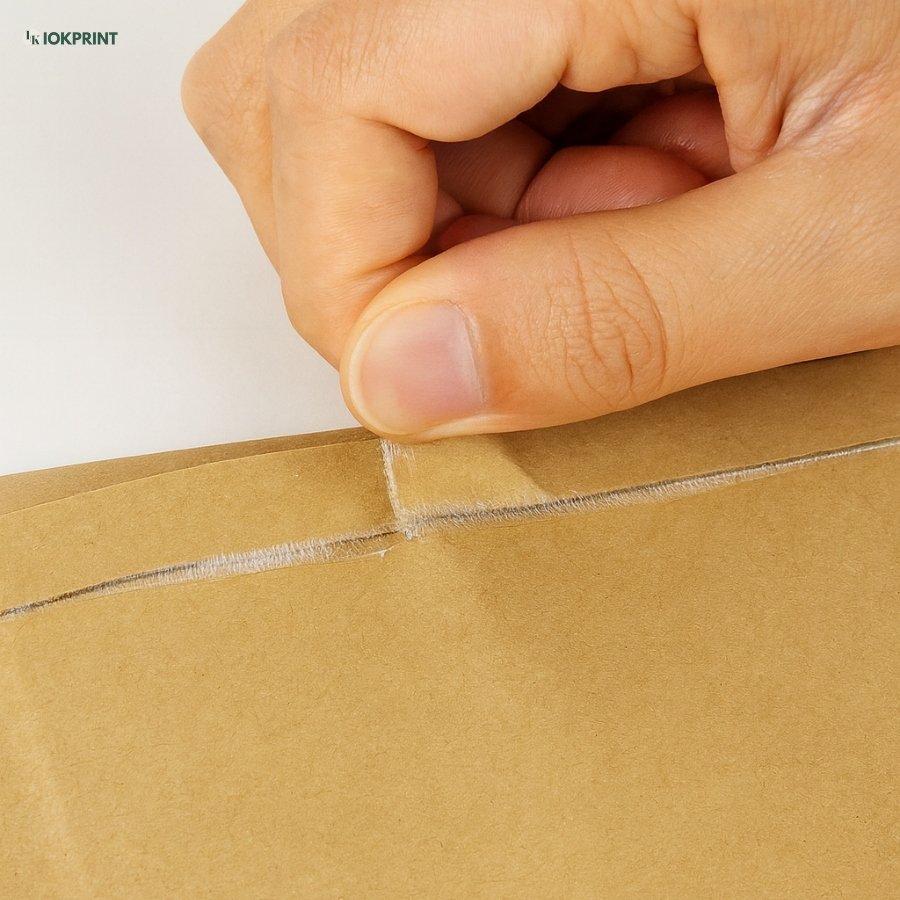

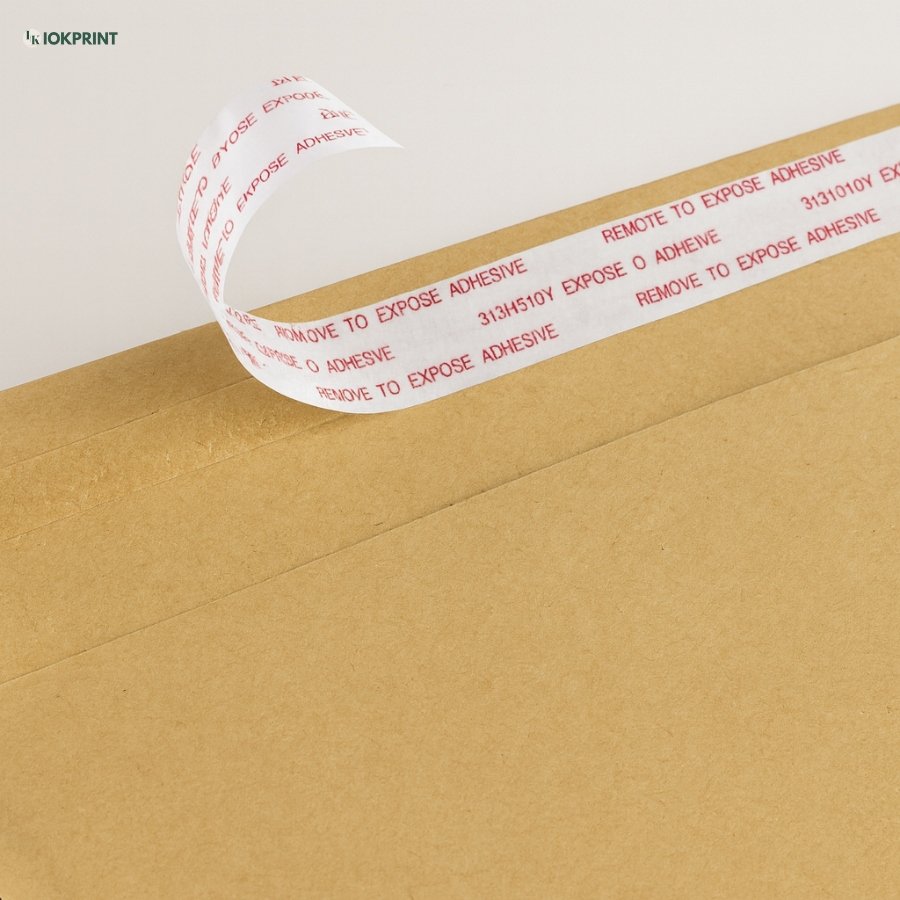

Our collection covers kraft mailer bags, kraft paper mailer bags, kraft bag packaging, kraft paper packaging bags, ziplock kraft paper bags, kraft paper ziplock bags, and kraft paper bag ziplock, suitable for e-commerce and secure packaging. We also manufacture small kraft paper bags, large kraft paper bags, kraft bag sizes, and heavy-duty options like 25kg kraft paper bags and 1 kg paper bags for industrial use.

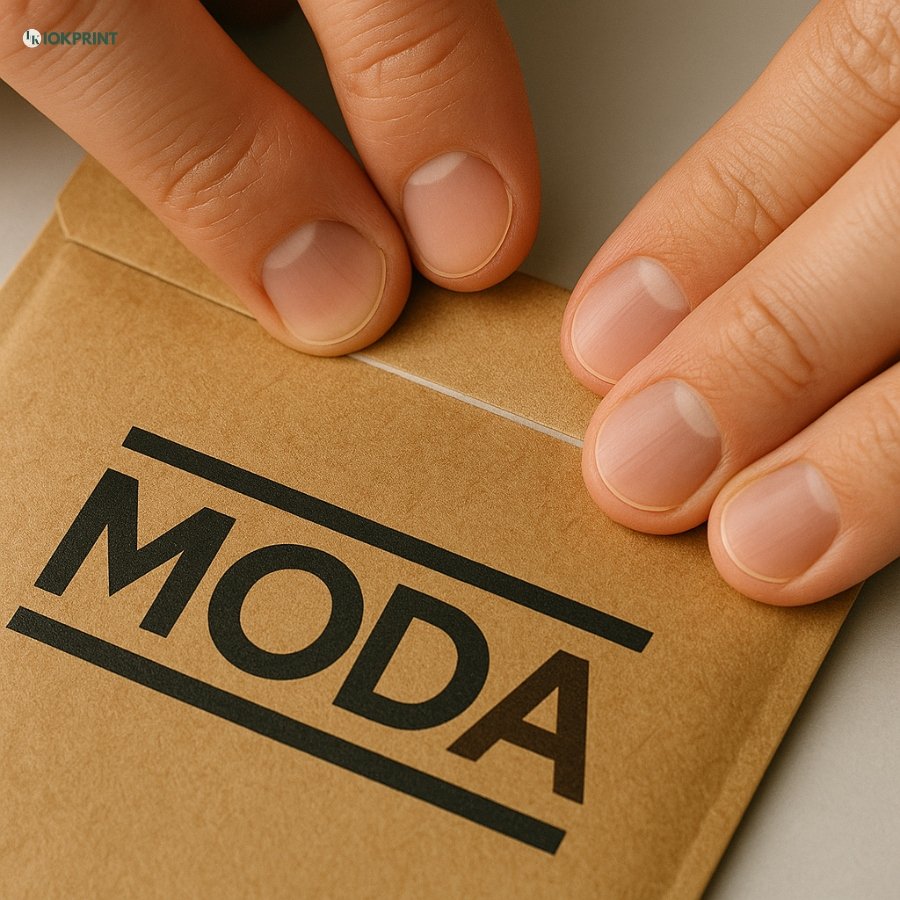

As leading kraft bag manufacturers, kraft bag suppliers, and kraft paper bag wholesalers, we provide custom kraft paper bags, printed kraft bags, kraft bag printing, and kraft paper bag design services with logo branding. Our products are made using high-quality kraft paper bag raw material, ensuring strength, sustainability, and a premium natural look.

We supply across India, including kraft paper bag manufacturers near me, paper bag manufacturers in Delhi, Chennai, Coimbatore, Tirupur, Sivakasi, Indore, Tamil Nadu, and major wholesale markets like Sadar Bazar, Parrys, and Chennai wholesale hubs. Our offerings include paper carry bags, brown carry bags, paper carry bags wholesale, paper bags wholesale price, paper carry bag price per kg, and paper bags pack of 100 for bulk buyers.

Whether you need gift paper bags wholesale, small paper bags for return gifts, paper bag for gift big size, carry bags for gifts wholesale, or cheap paper bags wholesale, we deliver consistent quality, competitive pricing, and reliable supply. Recognized among the top 10 paper bag manufacturers in India and counted among the largest paper bag manufacturers in India, we are your one-stop solution for sustainable paper packaging.

Faq

Welcome to our FAQ section. Here, you’ll find answers to common questions about our services. We aim to provide you with helpful information in a clear and straightforward way. If you can’t find what you’re looking for, feel free to reach out to us directly.

Kraft bags are made from kraft paper, a material derived from wood pulp. Known for their durability and eco-friendliness, kraft bags are often associated with a natural, rustic appearance. They are popular in industries like food, fashion, and boutique retail, as they can be recycled and composted easily.

The word “kraft” comes from the German word for “strength”. It describes the paper’s durability, elasticity, and resistance to tearing — all of which make it one of the strongest paper packaging materials on the market.

Kraft paper is also known as kraft paper and is a paper made from wood fibre pulp. Its inventor was the Swede Carl Dahn, who developed it in 1884 and its name comes from the German: “Kraft” means strength or vigour.

Of course, in the food industry packaging Kraft paper is also very popular, food grade Kraft paper performance is very superior, not only with moisture-proof or waterproof, and oil immersion, low temperature freezing, long expiration period and other characteristics.

Kraft paper is the most used material in packaging. There are a few different versions of kraft paper including 100% recycled content, partial recycled content, to 0% recycled content, also known as virgin paper. Paper that includes recycled content is heavier and less durable due to the shorter recycled wood fibers.

Packaging Industry

Food Packaging: Virgin kraft paper is non-toxic and food-safe, commonly used for takeaway bags, cake liners, and meat wraps. Consumer Goods Packaging: Favored by sustainable brands for its printability and rustic appearance.

Kraft paper’s primary raw material is wood pulp, usually from softwoods, made using the strong sulfate (kraft) process, often using virgin fibers but sometimes incorporating waste paper or agricultural residues like straw for eco-friendlier options. Key components include softwood/hardwood chips, water, and chemicals (like sodium hydroxide & sodium sulfide for “white liquor”) to break down lignin and release strong cellulose fibers. Wood Pulp (Virgin): The main ingredient, typically from softwood (pine, spruce) for high strength, but hardwoods can also be used. Recycled Fibers: Waste paper, paperboard, and scraps are used, especially in duplex boards or recycled kraft paper. Agricultural Residues: Straw, bagasse, and other plant fibers can supplement wood pulp. Chemicals: Essential for the kraft pulping process, including NaOH (sodium hydroxide) and Na2S (sodium sulfide). Strength: The kraft process preserves the length and strength of cellulose fibers, giving kraft paper its durability. Sustainability: Using renewable wood pulp and recycled materials makes it an eco-friendly choice.

The three main types of packaging, categorized by their place in the supply chain, are Primary (direct contact with product, e.g., bottle), Secondary (groups primary packs, e.g., cardboard box for bottles), and Tertiary (bulk for transport, e.g., pallet with boxes). Each layer serves distinct functions, from consumer appeal and protection to logistics efficiency. Definition: The first layer, directly touching the product, often called the consumer or retail packaging. Purpose: Protects, preserves, secures the product, provides key info, and attracts the customer. Examples: A soda can, a plastic fruit container, a medicine blister pack, or a shampoo bottle. Definition: Contains and bundles multiple primary packages. Purpose: Adds another layer of protection, helps with inventory management, and creates multi-packs. Examples: The cardboard box holding several cans of soup, a plastic ring holding drink bottles, or a box of cereal. Definition: Used for bulk handling, storage, and large-scale transportation. Purpose: Facilitates efficient movement and protection of large quantities through the supply chain. Examples: A wooden pallet with shrink-wrapped boxes of goods, or large shipping crates.

Kraft paper is made from wood pulp, a renewable resource, which makes it more sustainable than other packaging materials. Additionally, kraft paper is biodegradable and can be recycled, which means it has a lower impact on the environment than plastic or Styrofoam packaging.

Named after the German word for strength, kraft paper boxes are brown-colored material made from a unique process that is more durable than standard cardboard boxes.

The number of paper bags in 1 kg varies greatly by bag size and paper thickness (GSM), but common 1 kg capacity kraft paper bags often come in packs of 40 to 100 bags per kilogram, with lighter, smaller bags yielding more and heavier, larger bags fewer, but generally expect around 100 light-duty bags or fewer for stronger ones, as one bag might weigh 10-20 grams. Paper Weight (GSM): Thicker paper (higher GSM) means heavier bags, so fewer fit in 1 kg. Bag Size: Larger dimensions (length, width, height) increase weight, reducing the count. Design: Handles, gussets (bottom/side folds), and reinforcements add weight. A 70 GSM kraft bag designed for 1 kg content might yield 100 bags per kg. A heavier, larger bag (e.g., for a 1 kg cake box) might contain only 20 bags per kg, as each bag weighs around 20 grams. A medium-sized pack for groceries might have 40 bags per kg. You need the specific paper weight (GSM) and dimensions of the bags you’re using, as manufacturers list them by weight capacity, not necessarily by how many fit into a kilo of other bags.

Kraft paper GSM (Grams per Square Meter) varies widely, from lightweight <<a>50 GSM</a> for wrapping to heavy-duty ><a>200 GSM</a> for strong liners, with common weights like 80, 120, 150, 180 GSM used for packaging, bags, and boxes, determining its thickness and strength (Bursting Factor – BF) for different applications, notes CarePac, Shree Varudi Paper Mill, and Astron Paper & Board Mill. Lightweight (40-100 GSM): Thin, flexible, used for wrapping, delicate item protection, or inner layers. Medium (100-150 GSM): Standard for general packaging, shopping bags, and lighter 3-ply boxes (e.g., cosmetics). Heavy Duty (180-300+ GSM): Stronger grades for corrugated boxes, heavy sacks, and durable packaging. Application: Higher GSM for strength (corrugated boxes), lower for flexibility (wrapping). Strength (BF): Higher GSM often means a higher Bursting Factor (BF), indicating better durability. Material: Wood pulp kraft and recycled kraft have different ranges. 80 GSM: Common for general packaging rolls. 125-180 GSM: Standard for kraft liner board in corrugated board. 180-200 GSM: Good for medium-strength packaging and paper bags. In essence, the higher the GSM, the thicker, heavier, and stronger the kraft paper.

The document outlines the Indian Standard IS 1397:2020 for Kraft Paper used in packing and wrapping, detailing its specifications, grades, and requirements.

Reviews

There are no reviews yet.